We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

PH/JIG/M - Pocket hole jig mini

PH/JIG/M

Trend Pocket Hole Jig Mini - Portable Pocket Hole Jig

- Compact design perfect for repair work in situ on furniture, cupboards, and cabinets.

- Supplied with twin bases for use on new work and repairs for increased diversity.

- Fully adjustable from 18mm to 54mm centres for twin holes or stripped down for single pockets; ideal for repairs or joints on thinner components.

- Comes ready to use, complete with drill, driver bit and screws.

- High quality all metal build quality for durability, solid performance and consistency in any project.

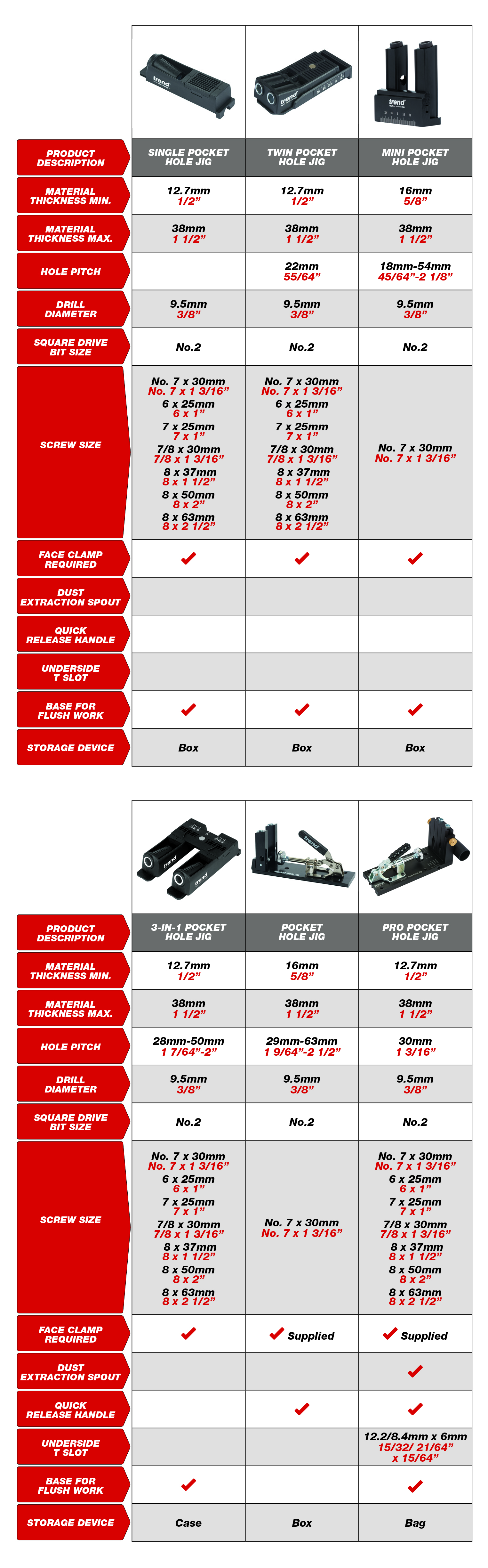

- Material thickness min.

- 16 mm

- Material thickness max.

- 38 mm

- Material width min.

- 38 mm

- Hole pitch

- 18 mm-54 mm

- Drill diameter

- 9.5 mm

- Square drive bit size

- No.2

- Screw sizes

- Fine No.7 x 30 mm

- Drilling angle

- 15 degrees

| Product Image | Product Ref | Diagram No | Description | Quantity Required | Price for 1 |

|---|---|---|---|---|---|

|

PH/7X30/500 | 008 | Square drive, self-tapping, solid steel wood screws coated with Zinc to protect against rusting, ideal for a variety of indoor projects. 30mm length coarse thread to suit 19mm hard woods such as oak, ash, maple and more. Designed for use with Pocket Hole Jigs.

|

1 | €19.18 |

|

PH/DRILL/95 | 011 | Pocket Hole Drill - 9.5mm diameter

|

1 | €26.77 |

Videos

Pocket Hole Jig & Mini Pocket Hole Jig Video

Video demonstrating the functions of the Pocket Hole Jig and the Mini Pocket Hole Jig.