We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

PH/JIG/AK - Pro Pocket Hole Jig

PH/JIG/AK

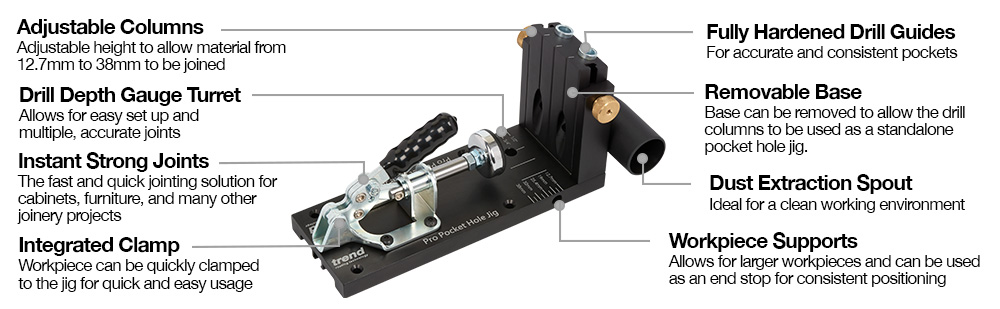

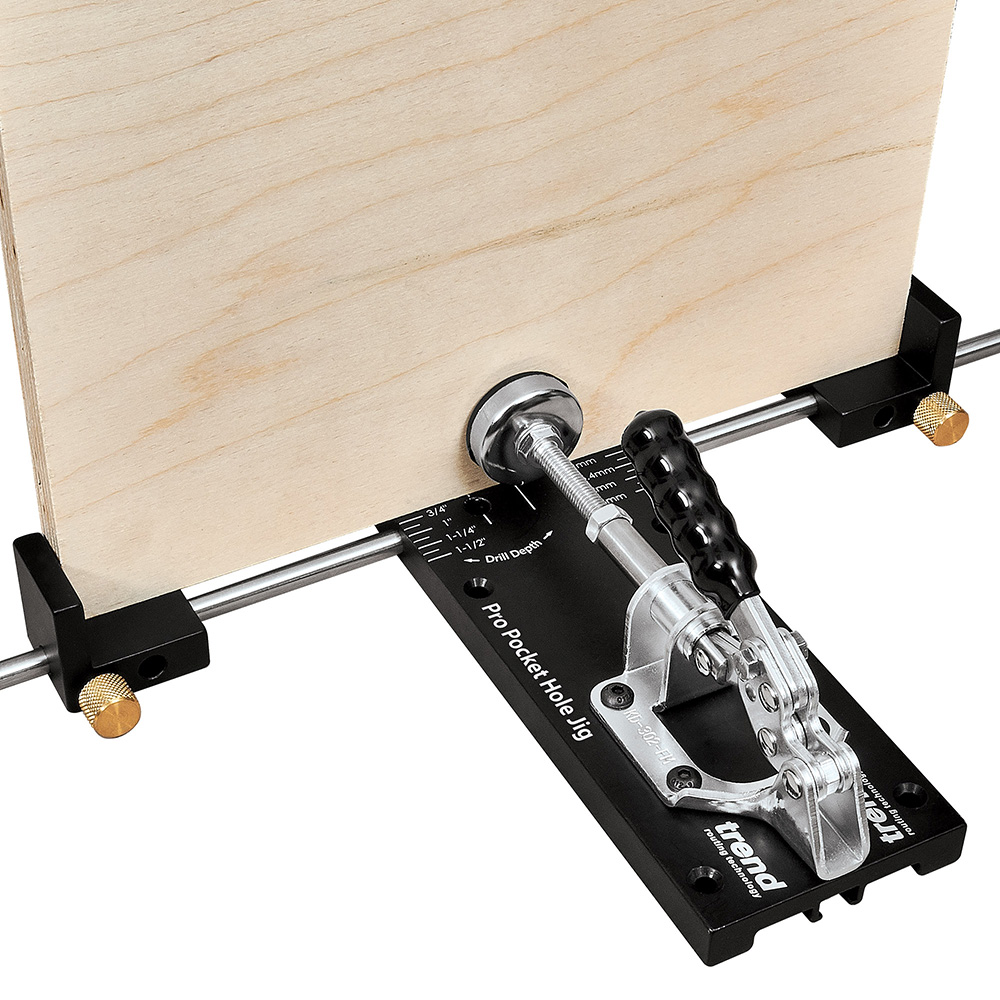

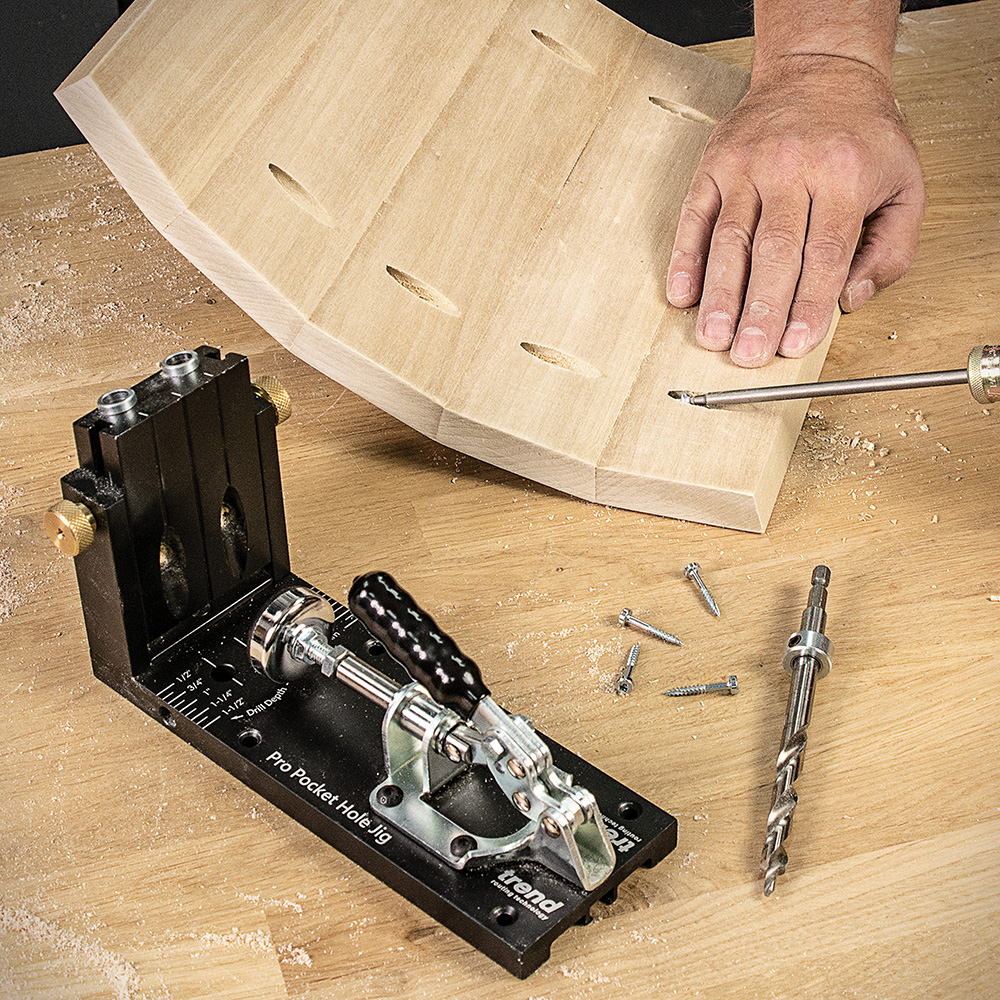

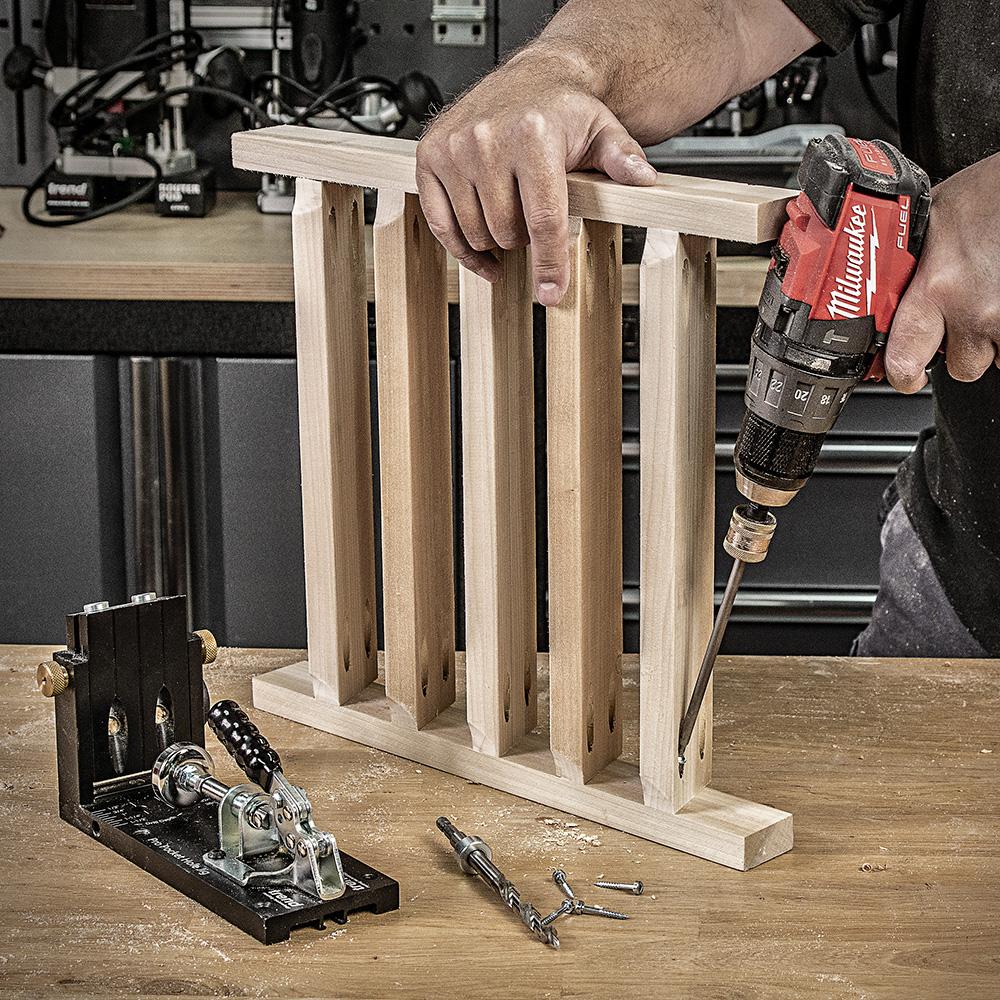

All-metal Pocket Hole Jig for drilling 9.5mm pocket holes in a range of material thicknesses. Twin 30mm centred pocket holes are ideal for large builds such as wardrobes, bookcases and cabinets. Can be bench-mounted for batch work or guides can be used independently for in-situ internal & external applications.

- Full Length Hardened Drill Guide Bushes for long life and accurate drilling.

- Material Thickness Gauge allows fast checking of material thickness without the use of a tape measure.

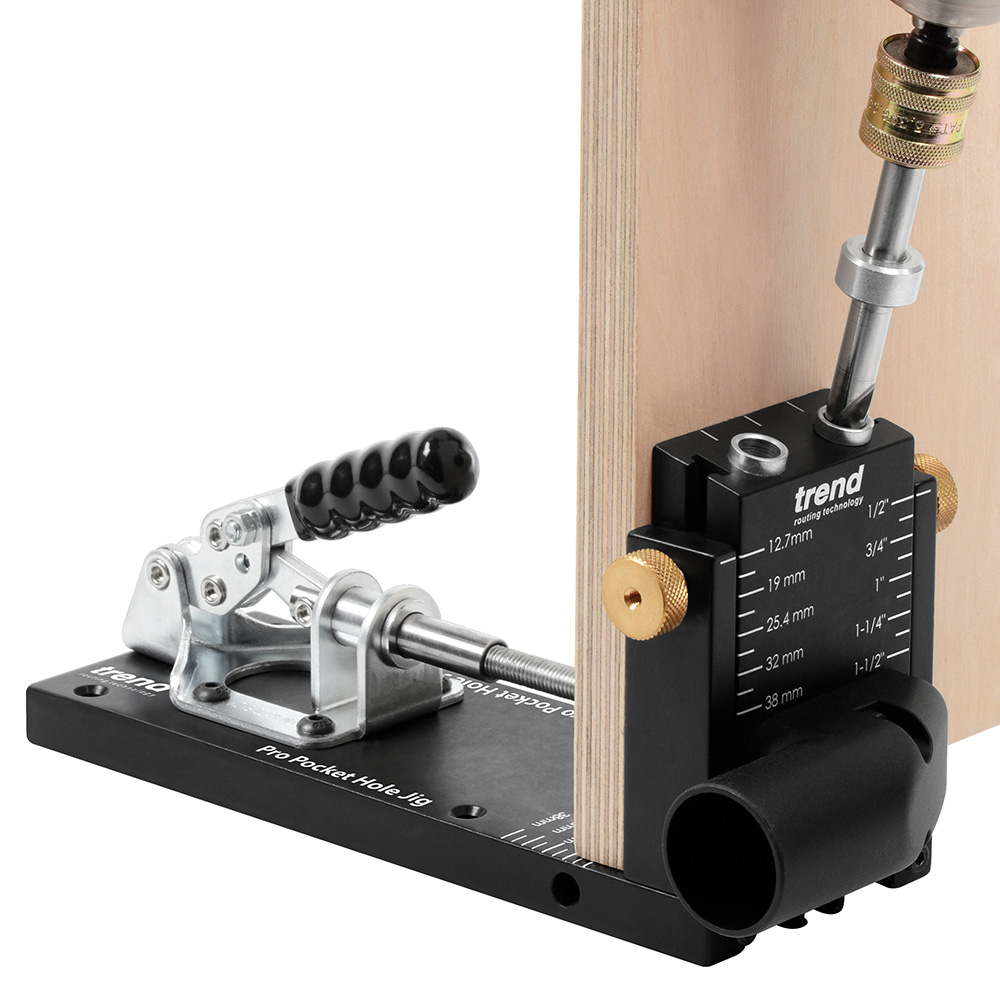

- Drill Bit Setting Turret for setting the correct drill depth to the material thickness.

- Work Support Rods prevent twisting when drilling longer material.

- Removable Drilling guides allows the column to be used separately for repair applications.

- Guide Locking Knobs lock the drilling guide in place once height has been adjusted.

- Dust Collection Port efficiently clears dust and debris for faster, cleaner drilling.

- On-Board Adjustable Clamp with quick-release mechanism.

- Non-Marring Clamp Pad to prevent pressure marks on the workpiece.

- T-Slot Clamp Guide supports the use of rail clamps to securely hold the jig to a work surface.

- Countersink Screw positions allows the jig to be screwed to a base board for extra support.

- Custom Carry Bag designed to optimise storage space.

- Material thickness min.

- 12.7 mm

- Material thickness max.

- 38 mm

- Material width min.

- 38 mm

- Hole pitch

- 30 mm

- Drill diameter

- 9.5 mm

- Square drive bit size

- No.2

- Dust spout ID

- 30 mm

- Underside T slot

- 12.2/8.4mm x 6mm

- Drilling angle

- 15 degrees

- Screw size

- Fine No.7 x 30 mm

- Screw sizes

- Coarse No.7 x 25 mm, No.7/8 x 30 mm, No.8 x 38 mm, No.8 x 50 mm, No.8 x 63 mm

| Product Image | Product Ref | Diagram No | Description | Quantity Required | Price for 1 |

|---|---|---|---|---|---|

|

SNAP/SQ/2B | 11 | Trend Snappy Robertson No2 Driver Bit - 150mm long

|

1 | €11.68 |